Auto Degas, Final Sealing & Sizing Machine , Pouch Cell Assembly Process

Functionality Overview:

This equipment specializes in automatic liquid extraction and vacuum packaging for flexible lithium-ion batteries, encompassing a comprehensive workflow:

Auto Feeding Flexibility:

Supports various feeding modes like tray loading, bulk material box insertion, conveyor linking, or cartridge feeding, tailored to needs.Precision Processing:

Aligns batteries into cavities, executes lateral sealing, pierces for vacuum encapsulation, removes air pockets, performs a second seal, and conducts side voltage testing.Custom Cutting & Folding:

Cuts precisely on left and right sides, with options for single or double fold edges, followed by tailored glue dispensing.Additional Features:

Includes hot edge shaping, optional battery thickness measurement,QR code scanning, weighing, and NG (not good) product sorting.Efficient Discharge:

Offers customizable discharge options such as tray unloading, strip feeding, or collection via blister trays.

Technical Highlights:

Automated Processing:

Mechanical arms guide materials into sealing cavities, followed by automatic gluing, piercing, degassing, and packaging, ensuring streamlined operations.Air Bag Optimization:

Pre-cutting feature trims excess air bag edges to prevent electrolyte contamination from residue.Quality Assurance:

Post-packaging short circuit testing identifies and removes NG (non-conforming) products.Precision Edge Trimming:

Dual-station alignment ensures accurate trimming of air bag and side seals.Gentle Battery Handling:

A buffered hot side design prevents battery damage during processing.Edge Cutting Precision:

Achieves ±0.15mm accuracy in cutting edges.Enhanced Packaging Positioning:

Dual realignment before packaging guarantees ±0.15mm positional accuracy.Easy Maintenance:

Detachable sealing blocks facilitate quick and effortless upkeep.Durable Cutting Tools:

Cutting mechanisms withstand up to 500,000 uses without needing repairs or sharpening.Integrated Weighing System:

Captures weighing data, binds it with barcodes, and inputs into a database for comprehensive tracking and management.

Technical Parameters

| Item | Common parameter |

| Outlook size | L8000XW1300XH2300 |

| Machine Weight | ≈2.5T |

| Power rate | 15kW |

| Power supply | AC220/50HZ |

| Air source | ≥0.6MPa50L/min |

| Vacuum source | ≤-95KPa 400L/min |

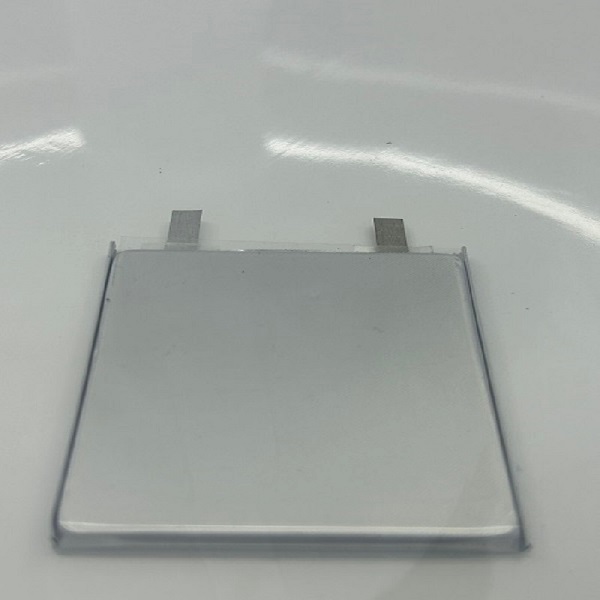

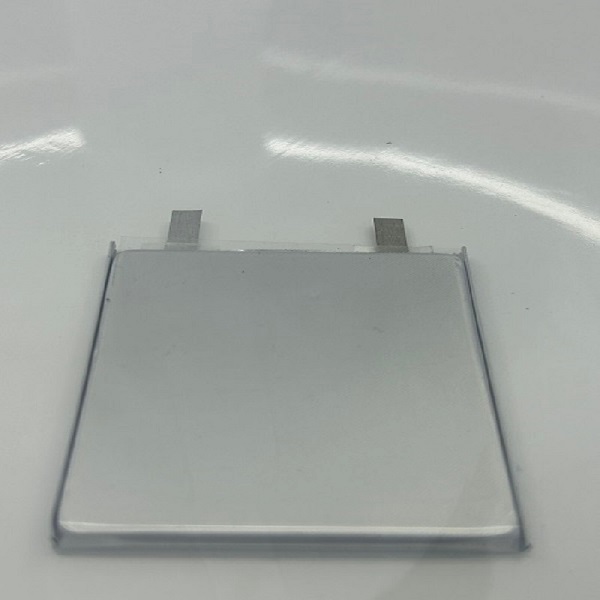

| Scope of applicable products | L10—50mm,W10—40(No air bag)T2—10 |

| Equipment output | ≥15PPM |

| Qualified rate | ≥99.6% |