Semi-Automatic Stacking Machine , 250 Type , Cells Making

Functionality Overview:

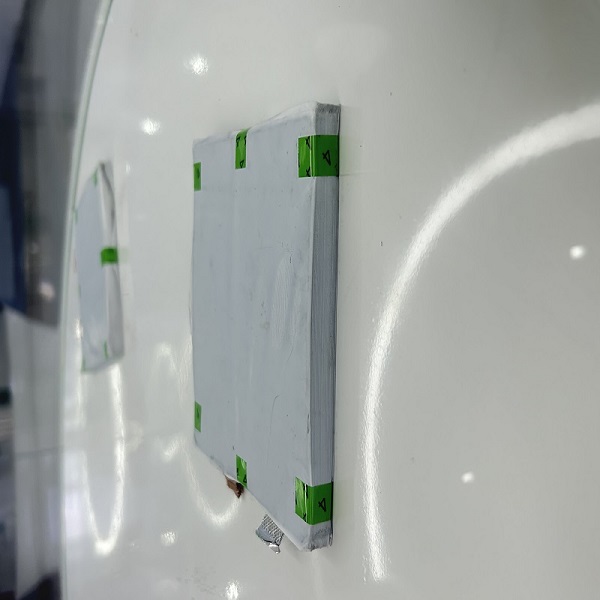

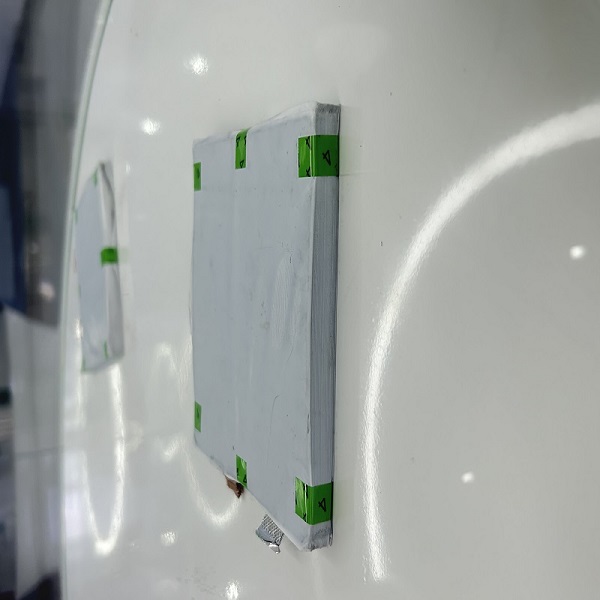

Our Z-Shaped Lamination Device specializes in the precise and efficient lamination of anode and cathode sheets alongside separators for lithium-ion battery cells. Offering flexibility, the anode can be folded to align with either the same or opposite side of the cathode tabs, ensuring tailored assembly to various battery designs. Post-lamination, the separator undergoes heating and attachment of side glue, further reinforcing structural integrity and performance.

Optional Customizations:

Offers dual pasting modes:

select between side glue or flat glue application.Customizable end-coil separator management with adjustable end-coil winding counts.

Seamless integration with downstream conveyance lines for continuous workflow.

Upgrade potential to include a cutting and folding mechanism for process expansion.

Integrated dust removal post-separator cutting, ensuring a clean and contaminant-free end product.

Technical Specifications:

Model 250TypeElectrode Positioning Mechanism:

Mechanical positioning for accuracy and repeatability.Production Speed:

Achieves a remarkable efficiency of 0.5 to 1 second per piece.Compatibility:

Supports electrode sizes ranging from Length 150-250mm and Width 80-200mm, catering to a broad spectrum of battery designs.Stacking Mechanism:

Employing a cam-actuated press claw for stable and consistent stacking.Quality Control Features:

Incorporates ultrasonic angular detection as a standard, ensuring defect-free lamination.

Offers precise alignment with ≤±0.2mm tolerance between adjacent electrodes, ≤±0.4mm for overall electrode alignment, and ≤±0.4mm between electrodes and adjacent separators.

Separator cutting and turnaround cycle completed in ≤12 seconds, enhancing throughput.

Dust Management:

Supplemented with a top-mounted FFU (Fan Filter Unit) to maintain a dust-free operating environment.Static Elimination:

Standard inclusion of separator electrostatic removal for process reliability.MES Compatibility:

Fully capable of interfacing with MES systems for comprehensive production monitoring and control.

This meticulously designed Z-Shaped Laminator represents the pinnacle of battery manufacturing technology, combining precision engineering, adaptability, and advanced quality control measures to ensure the production of high-performance lithium-ion batteries.