PRODUCT DESCRIPTION

Straight Line Electrolyte Filling Machine For Pounch Cell

Function Description

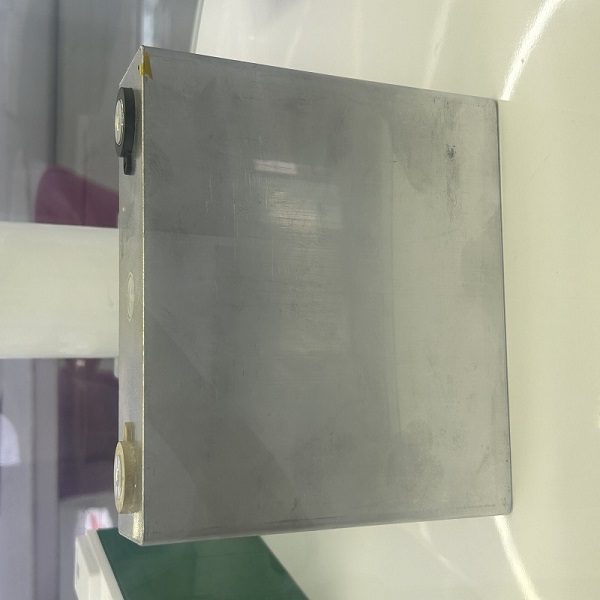

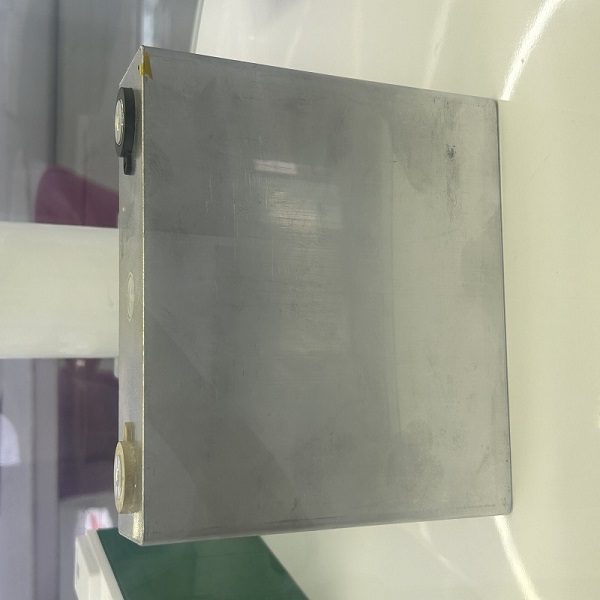

The equipment is mainly used for automatic conventional/vacuum injection of lithium battery with prismatic Al shell battery

The conveyor belt coming material, scan code before filling, short-circuit & Hi-pot test, Weigh before filling, bad product sorting collection, automatic liquid injection on the fixture,sealing detection before filling, automatic routine, high and low voltage soaking, filling cup residual liquid collection

Filling cup and nozzle clean, after injection liquid conveyer belt clamp, liquid injection after weighing, automatic liquid injection DMC clean nozzle, note on the liquid glue nail, plastic nail detection, conveyor belt discharging,etc

Technical Specifications:

Advanced Battery Injection Technology

Our injection system introduces a groundbreaking approach to battery filling, emphasizing precision, cleanliness, and efficiency to elevate manufacturing standards:

Injection Method:

Employing a no-pressure-differential technique, the system injects electrolyte into batteries without creating internal or external pressure discrepancies. This method safeguards against battery casing deformation during the injection process, particularly under positive and negative pressure conditions.Optimized Soaking Time:

By streamlining the injection procedure, our system significantly reduces the soaking time required for batteries, thereby enhancing overall equipment efficiency and throughput.Injection Pressure Control:

During electrolyte injection, a precisely regulated positive pressure of 0.6 MPa nitrogen is maintained both inside and outside the battery. This balanced pressure application ensures uniform filling and minimizes potential stress on the battery structure.Enhanced Cleaning Measures:

Prior to injection, an integrated injection cup and nozzle cleaning system is activated. This proactive measure improves injection accuracy while preventing any cross-contamination from the nozzle to the battery, ensuring product purity.Residual Liquid Management:

Post-injection, a residual liquid connection system is implemented to collect excess electrolyte, effectively preventing shell contamination and maintaining a clean production environment.Innovative Injection Nozzle Design:

Tapered injection nozzles are utilized to navigate the contours of the battery injection port seamlessly, avoiding angular connections that could trap electrolyte and hinder effective cleaning. This design promotes complete cleaning and minimizes process inefficiencies.Flexible Production Capacity:

The equipment’s production capacity is dynamically scalable, unbound by fixed process times. As production demands grow or change, additional injection units can be incorporated into the system to effortlessly match production targets, ensuring that your manufacturing capabilities remain agile and adaptable.

Technical Parameters

| Item | Common parameter |

| Outlook Size | L14590mm×W3000mm×H2753mm |

| Machine Weight | ≈10.5T |

| Power rate | 15kW |

| Power supply | AC380V/50Hz |

| Air source | 20.7MPa 30L/s(Utilization rate 50%) |

| Vacuum source | ≤-95kPa60L/5 |

| Nitrogen | ≥0.6MPa60L/s |

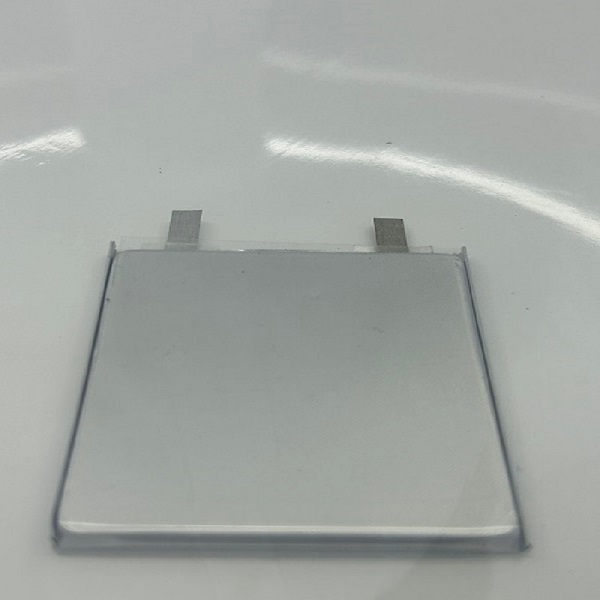

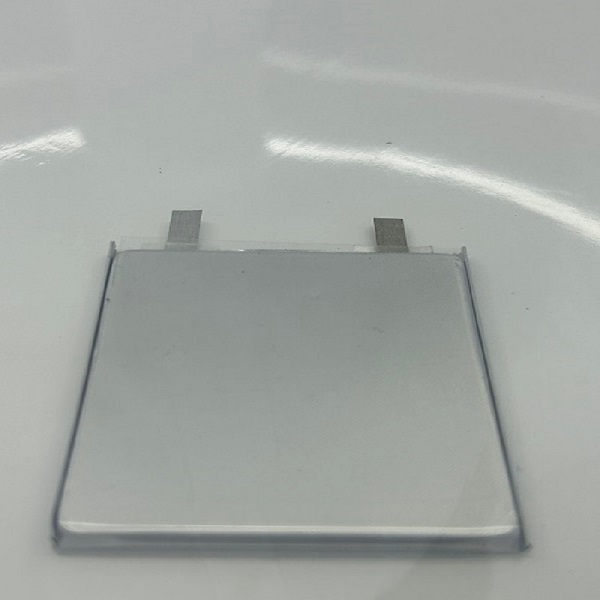

| Scope of applicable products | L(80~220mm)×W(60~180mm) ×T(15~60mm) |

| Equipment output | ≥12PPM(Total standing pressure time≤480s) |

| Qualified rate | ≥99.5% |

| Action | ≥97% |

| Filling amount | 0~800gAdjustable(can be made according to customer requirements) |

| Filling pump accuracy | ±0.2% |

| Filling accuracy | ±1.1% |

| Weigh accuracy | ±0.1g |

In summary, our battery injection technology sets new benchmarks in precision, cleanliness, and adaptability, offering manufacturers a future-proof solution that bolsters productivity while maintaining the highest levels of product quality.