The stacker is a highly efficient and precise device designed for the z-shaped lamination of anode and cathode plates, as well as the separator, in lithium-ion battery cells. This advanced equipment is essential for the production of high-quality batteries with consistent performance.

The stacker is equipped with specialized technology that allows for the precise folding of the anode, whether on the same side or the opposite side of the anode. This ensures that the layers are properly aligned and securely bonded together, resulting in a stable and reliable battery cell.

With its user-friendly interface and customizable settings, the stacker offers flexibility and ease of operation for manufacturers. Its high-speed capabilities and accuracy make it an indispensable tool for streamlining the battery production process and achieving optimal results.

In addition, the stacker is built with durable materials and components to ensure long-lasting performance and minimal maintenance requirements. Its robust construction and reliable operation make it a valuable investment for any battery manufacturing facility.

Overall, the stacker is a cutting-edge solution for achieving precise and efficient lamination of anode and cathode plates in lithium-ion battery cells. Its advanced features and superior performance make it an essential tool for producing high-quality batteries that meet the demands of today's technology-driven world.

The stacker is a versatile and efficient piece of equipment designed to streamline the stacking process in various industries. With optional configurations available, users have the flexibility to choose between pasting side glue or flat glue modes, depending on their specific needs. Additionally, the end coil separator and the number of end coils can be easily adjusted to accommodate different production requirements.

One of the key features of the stacker is its seamless integration with the whole line conveying system, allowing for smooth and continuous discharge of the stacked cells. This ensures optimal efficiency and productivity, making it an essential tool for any manufacturing operation.

Constructed with high-quality materials and precision engineering, the stacker is built to withstand the rigors of daily use and deliver consistent performance. Its user-friendly interface and intuitive controls make operation simple and hassle-free, while its compact design allows for easy integration into existing production lines.

Overall, the stacker is a reliable and efficient solution for stacking operations, offering customizable configurations and advanced features to meet the diverse needs of modern industries. Trust in the stacker to enhance your production processes and maximize efficiency.

The characteristics of the stacking machine.

High speed: Linear motor feeding, linear motor driving stacking table movement, achieving high-speed stacking, with a speed of up to 0.3s/pcs.

The diaphragm is actively unwinded by the servo, and the tension is controlled by the servo torque. The diaphragm buffer and stacking platform move synchronously to supply the diaphragm, preventing it from stretching and deformation.

Measures for multi piece leakage: material box swing, segmented brush, robotic arm servo shaking to separate polar pieces, and ultrasonic sensor to detect multi piece leakage.

Corner detection of electrode lug: four Corner detection of electrode lug and electrode lug are detected, and defective electrode lug is automatically discharged.

The FFU fan at the top of the equipment supplies air, and the industrial dust removal system vacuums multiple workstations such as the material box and positioning, allowing the internal air of the machine to circulate and suck away the floating powder inside.

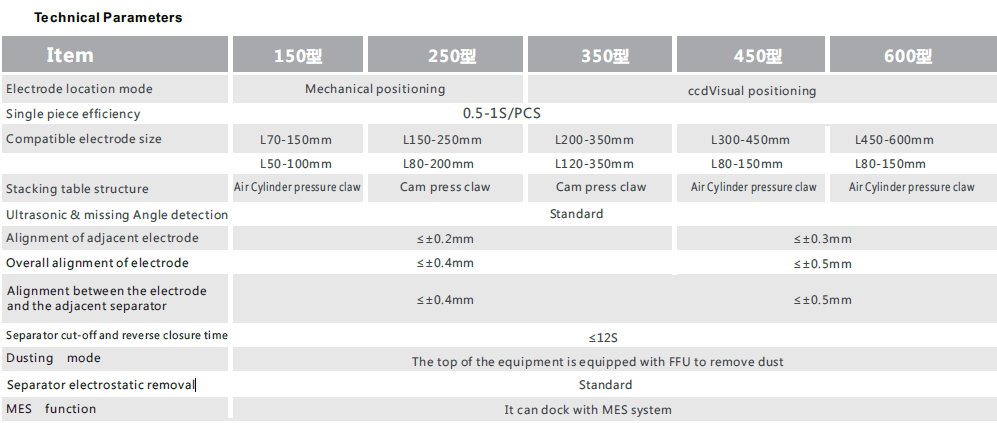

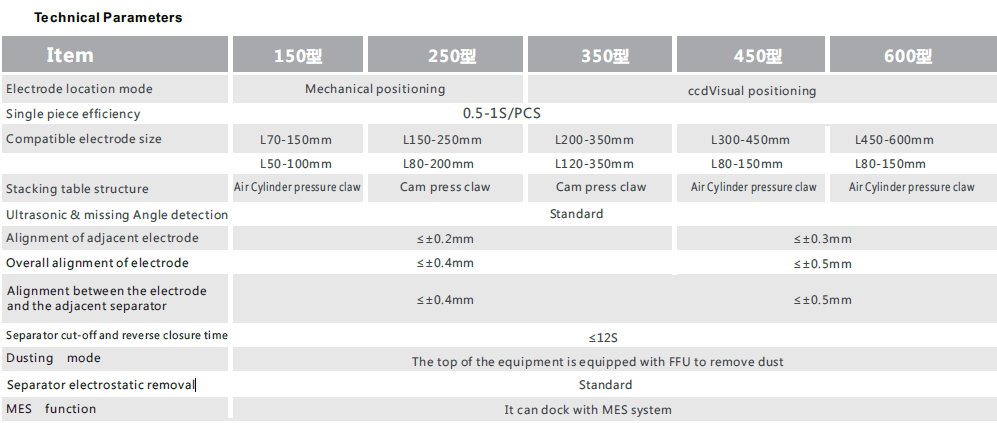

Technical Parameters