Function Description

Featuring advanced technology and high-quality components, the Electrode Auto Electrode Blanking Machine is built to deliver reliable performance and consistent results. Its automated cutting and forming capabilities ensure uniformity and accuracy in electrode production, meeting the stringent requirements of the industry.

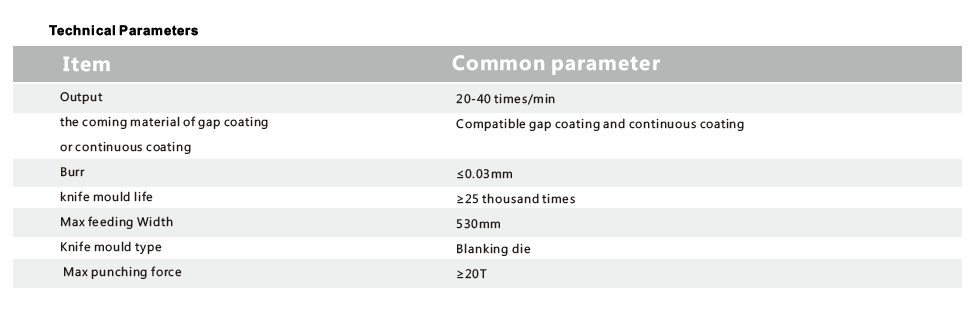

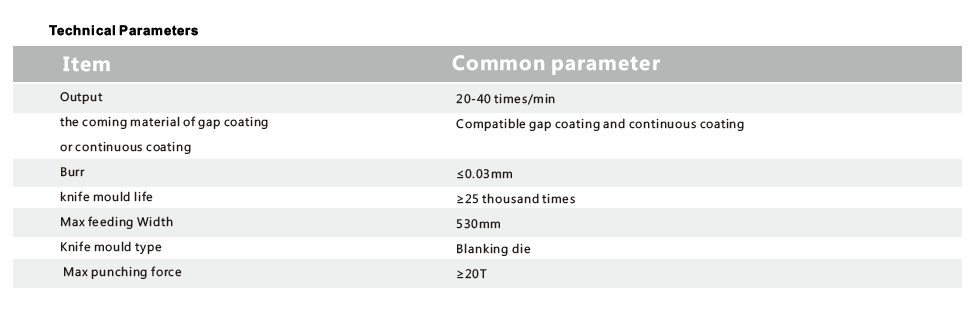

With user-friendly controls and a robust construction, this machine is easy to operate and maintain, making it a valuable asset for any lithium battery manufacturing facility. Whether you are producing gap coating or continuous coating electrodes, this versatile machine can handle a wide range of materials and specifications with ease.

Invest in the Electrode Auto Electrode Blanking Machine and take your lithium battery production to the next level. Experience the benefits of automation and precision in electrode manufacturing, and stay ahead of the competition with this cutting-edge solution.

The Electrode Blanking Machine Optional configuration is a highly efficient and versatile machine designed for the precise cutting and processing of electrodes. This machine features PET single release and single receipt capabilities, allowing for seamless operation and increased productivity.

Equipped with a mechanical arm to receive material, the Electrode Blanking Machine ensures smooth and reliable handling of materials throughout the cutting process. Additionally, the machine is equipped with labeling detection NG sorting, which helps to eliminate errors and ensure accurate processing of electrodes.

The use of the stacking machine for the material trough and the next process further enhances the efficiency of the Electrode Blanking Machine, allowing for seamless integration into existing production lines. The inclusion of a mechanical arm also provides added flexibility and precision in material handling, ensuring consistent and high-quality results.

Overall, the Electrode Blanking Machine Optional configuration is a reliable and advanced solution for electrode cutting and processing, offering a range of features to enhance productivity and accuracy in manufacturing operations.