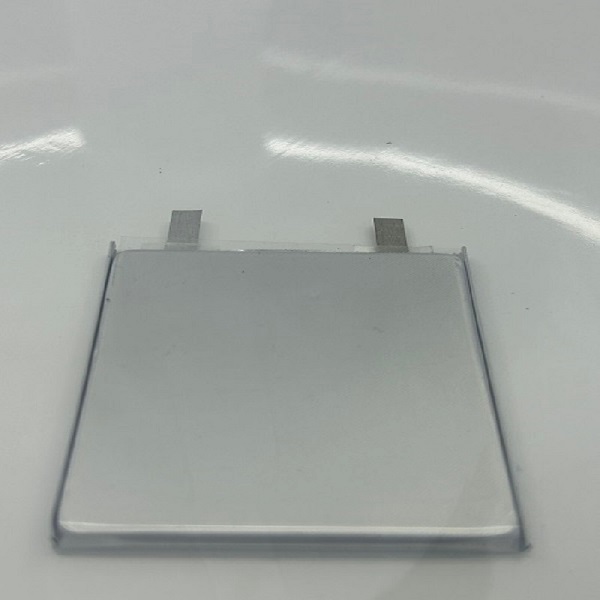

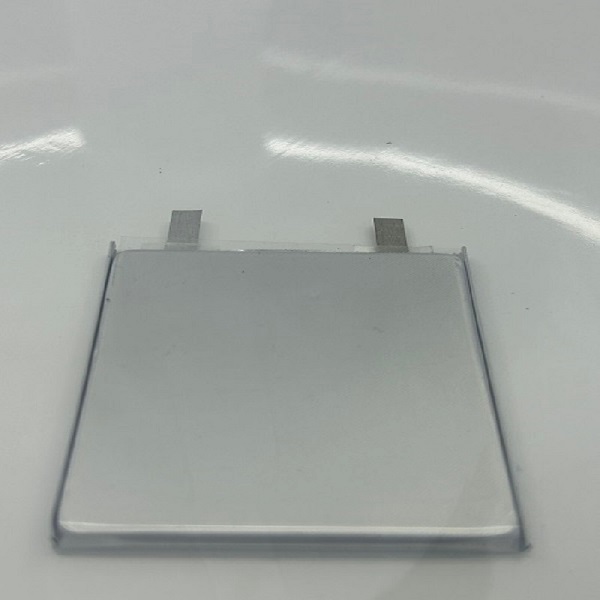

Optimizing EV Battery Assembly: The 400-Type Solution

The 400-Type Auto Tab Ultrasonic Welding Machine represents the pinnacle of innovation in pouch cell EV battery manufacturing technology, specifically designed for seamless stacking and winding processes. This sophisticated equipment integrates a multitude of advanced functionalities, including preand post-weld short circuit testing, automated feeding and tab welding, and intricate post-weld operations like tab cutting, bending, and surface finishing. It underscores a modular architecture that adapts effortlessly to individual production line configurations, ensuring peak performance tailored to your exact needs within the battery machine landscape.

Precision Engineering for Unmatched Quality

Adaptive Material Handling:

Boasting a flexible pre-weld material input system that supports belt conveyance, frame loading, or front-end configurations, this machine ensures a smooth workflow.

Defect Elimination Mechanism:

Integrated with a hot pressure test, it automatically detects and removes defective cells from the production stream, enhancing the integrity of the small car battery production line.

Positioning Precision:

Offering dual positioning modes—mechanical or advanced CCD—for critical stages, it guarantees pinpoint accuracy in cell alignment.

Electrode Identification & Dust Control:

Incorporates specialized features for cathode/anode differentiation and efficient dust extraction during pre-welding and final welding phases, vital for the ev battery production line.

Ultrasonic Weld Integrity:

Ensures robust welds free from voids, particulate dispersion, separator damage, or thermal insulation glue issues, preserving battery health.

Smart Integration for Efficiency & Traceability

CCD Vision System:

Optional CCD integration for real-time monitoring of tab positioning accuracy, further enhancing production quality.

Versatile Taping Options:

Customizable taping methodologies (flat, L-type, Z-type) to accommodate diverse battery designs across electrical appliance production line applications.

Continuous Operation:

Facilitates uninterrupted material changeovers for all components, optimizing uptime and throughput.

Post-Weld Charging Adaptability:

Offers flexible post-weld charging modes, adaptable to belt systems or feeding frames, streamlining the entire battery sealing machine operation.

Intelligent Control System:

Features an adaptable control unit with self-diagnostic and corrective capabilities, ensuring minimal downtime.

Performance Metrics Aligned with Industry Demands

Technical Specifications (400 Type):

Welding Mode:

Straight-line with tab opposition for precise joins.

Compatibility:

Catering to a broad product range with dimensions L200-350mm, W50-150mm, T5-15mm.

Accuracy:

Welding and taping precision within ±0.4mm, surpassing industry norms.

Output Rate:

Exceeds 12PPM, enhancing productivity in high-volume production line for battery environments.

Welding Method:

Utilizes flat welding for consistent results.

Yield Rate:

Achieves ≥99.6%, ensuring high-quality output.

Mechanical Efficiency:

≥95%, highlighting its robust operational consistency.

By integrating this 400-Type Auto Tab Ultrasonic Welding Machine into your production, you're not just adopting a piece of equipment; you're investing in a future-proof solution emphasizing technical excellence, and facilitating data connectivity with MES systems for unparalleled traceability and efficiency in battery manufacturing.