Semi-Auto Tab Welding Machine , 900 Type

Function Overview:

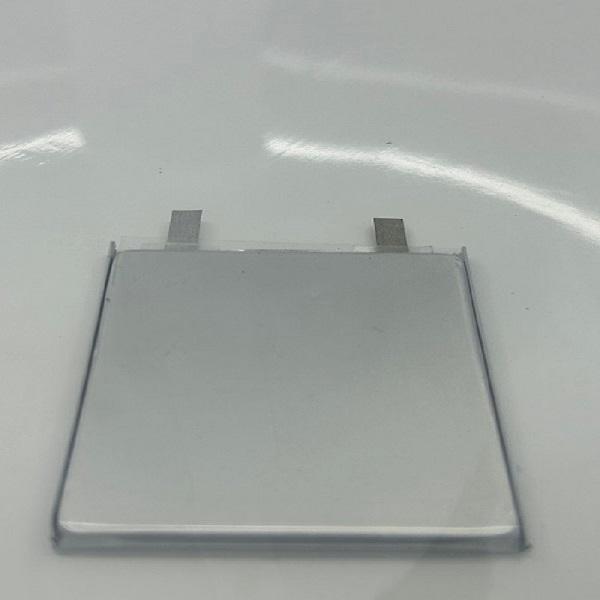

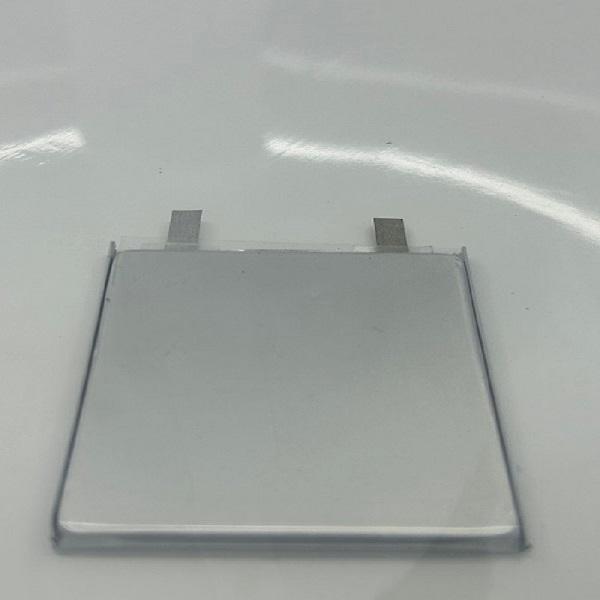

The equipment commences operation upon manual placement of the battery core onto the designated flattening and testing station. It initiates with a preliminary short-circuit test, advancing to execute pre-welding and vacuuming procedures for both positive and negative electrodes. This is followed by precise electrode trimming, primary welding, and vacuuming processes. The system seamlessly integrates automatic welding and adhesive application, culminating in a post-manual welding short-circuit examination. Notably, the equipment’s adaptability is heightened through interchangeable fixtures, empowering the manufacture of diverse product varieties, accommodating both single and double-ended pole ear cell configurations.

Technical Innovations:

Engineered to cater to the intricacies of single or double pole ear cell production, this equipment excels in pre-welding and main welding stages, fortified with safeguards against welding chip ingress into the cell and integrated vacuum functionality, ensuring pristine internal environments.

Welding Expertise:

Utilizes ultrasonic flat welding technology, delivering reliable and efficient bonding. Optionally, it supports welding with a protective film layer, adding an extra layer of security and quality control to the process.

Efficient Waste Management:

Precision Testing Capabilities:

Bonding Mechanism Advancements:

Boasts a rapid glue change mechanism, fortified with anti-adhesive properties to prevent clogging and an anti-cutting knife injury design, ensuring operator safety and uninterrupted workflow efficiency.

In summary, this equipment embodies a sophisticated blend of precision, adaptability, and safety-focused design, redefining standards in battery cell manufacturing and assembly processes.

Technical Parameters

( the product is constantly upgraded. The following parameters are for reference only )

| Item | 300 Type |

| Single head pole ear cell | L 150 ~ 350mm, W150 ~ 260mm |

| Double head pole ear cell | L 150 ~ 900mm, W50 ~ 150mm |

| The thickness of the battery | 5 ~ 18 mm |

| Position accuracy of polar lug welding | 土0.5mm

|

| Accuracy of TAB center distance position |

| Positioning accuracy of cutting ear |

| Tab and lug stripping force after final welding | ≥70N |

| Residual area of welding surface after welding | ≥60% |

| Life of cutting pole ear cutter | ≥300,000 / time (multiple grinding) |

| The equipment size | 8000mmx1800mmx2000mm |

| The power supply | AC380V, 50HZ, 25kw |

| Air supply | 0.5-0.7 MPA, 60 L/Min |

| Weight | 3 T |